The obliteration of humanity at the hands of robots has been displaced as the largest robot-related threat to mankind. A lack of human-robot amalgamation means a world where efficiency and productivity are put to the side, a far more devastating sight.

The modern business landscape requires organisations to evolve quickly to ensure survival. Robotic Process Automation (RPA) is key to this quest. But what is RPA and how does it work?

What is RPA?

RPA uses bots to automate repetitive tasks that were once performed by humans, with the aim to increase efficiency, streamline operations, and reduce the need for manual tasks such as data entry and extraction.

How does RPA work?

Rule setting

The journey of RPA begins by defining the rules for what actions the software bot should take, and when it should automate the process step. These rules are tailored based on the specific tasks that the bot is told to automate.

The information key

Once the rules are set, RPA takes control by reaching into your existing IT systems. It integrates with your applications, either through connections to databases and enterprise web services in the backend or through front-end or desktop connections.

Kick-off

With the rules defined and access to the necessary information, the bot gets to work. The tasks it can perform are wide-ranging – from understanding what’s on a screen, completing the right keystrokes, navigating systems, identifying, and extracting data, to performing a wide array of defined actions.

Performance, performance, performance

Once the bot is initialised and begins executing tasks, don’t sit back and relax. Continuously monitor its performance, vigilantly. It can be refined and improved based on its performance.

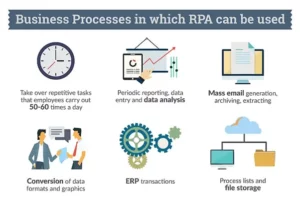

Business Process in RPA © UiPath (2023)

RPA in Procurement and Supply Chain Management

Supply chain management involves a wide range of tasks, many of which are repetitive and time-consuming. RPA can manage these tasks, allowing your organisation to concentrate on more strategic, human-centric tasks.

For example, RPA can interface with vendor, supplier, and retailer systems alike, synchronising efforts to enable just-in-time supply chains. It can also reduce planning time and errors by connecting significantly dissimilar systems across your supply chain.

Moreover, RPA can enable dynamic sourcing by tracking the costs of each item across multiple suppliers to get the best prices. It can streamline manufacturing in conjunction with RFID and geofencing to automatically track inventory levels and locations in real time. It can also support delivery and logistics by sorting items for shipping and matching them to the most efficient delivery routes.

Examples in P2P

Unilever partnered with UiPath to automate their Accounts Payable process. This reduced invoice processing time from 4 minutes to just 4 seconds per invoice (UiPath, 2019).

Nokia worked with Automation Anywhere to deploy over 500 bots handling procure-to-pay processes. This resulted in 90% faster processing times and 10% cost savings (Nokia, 2021).

Intel used Blue Prism’s RPA software to automate order creation and status updates between procurement systems and suppliers. They were able to redeploy over 35 FTEs towards more value-added work (Intel, 2020).

How to implement RPA for effective use

1. Understanding the Current Workflow: The first step is to get a clear picture of the existing processes.

2. Optimising the Processes: Before automating, it’s important to streamline and simplify the processes.

3. Setting a Broad Objective: The vision for digital transformation through RPA should be comprehensive and shared by all stakeholders.

4. Selecting the Right Partners : Combining RPA with other technologies like process mining and machine learning can yield better results.

5. Having Robust Technical Support: A strong technical support team, both in-house and from the vendor, is crucial for successful RPA implementation.

6. Implementing Rapid Changes: While it’s important to have a governance structure for the RPA solution, it’s equally important to remain agile and adaptable.

7. Evaluating and Scaling Up: After implementing RPA, it’s important to measure its effectiveness based on predefined metrics. This can help in identifying areas of improvement and deciding the next processes to automate.

While RPA indeed presents a compelling case for transforming procurement, it’s crucial to note that its true potential proliferates when it collaborates with human expertise. The synergy between human intellect and the efficiency of RPA creates a collaboration that drives innovation and excellence in procurement practices.

In conclusion, as we move into an era where technology is revolutionising every facet of business, RPA excels as a differentiator in procurement. Companies that embrace this technological marvel are not merely automating tasks; they’re fostering a culture of efficiency, accuracy, and strategic agility in their procurement endeavours.

For more information about RPA, please read our article Analogue to Algorithm: Pioneering Change in a Digital Frontier.

Get in Touch

If you are interested in discussing digital transformation or merely want to collaborate on a topic, then please reach out to Mark Ellis (Partner) or Joe Gibson (Head of Digital Innovation).

Published

December 19th 2023